Most master cylinders have a “tandem” design (sometimes called a dual master cylinder).

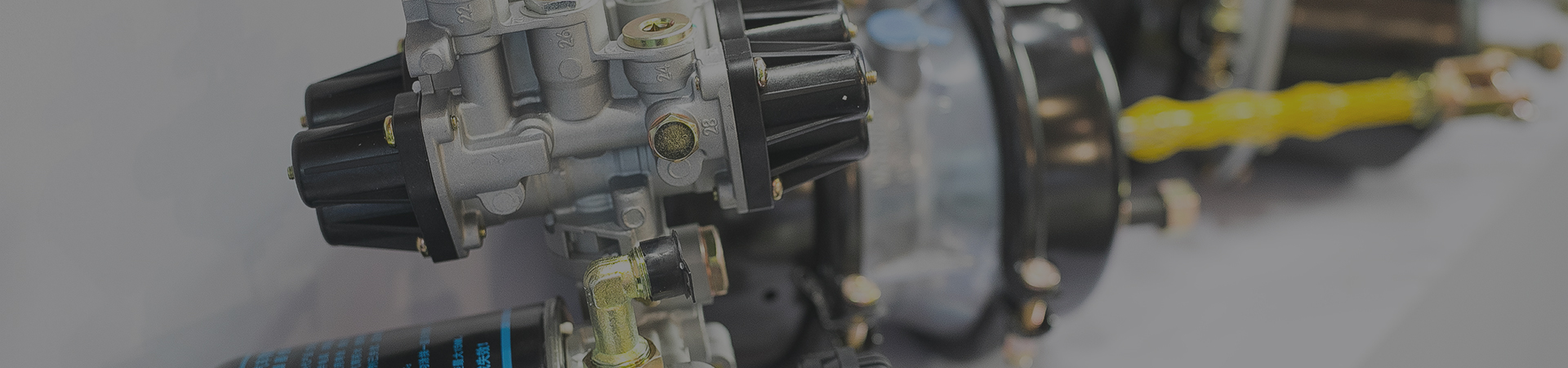

In the tandem master cylinder, two master cylinders are combined inside a single housing, sharing a common cylinder bore. This allows the cylinder assembly to control two separate hydraulic circuits.

Each of these circuits controls the brakes for a pair of wheels.

The circuit configuration can be:

● Front/rear (two front and two rear)

● Diagonal (left-front/right-rear and right-front/left-rear)

This way, if one brake circuit fails, the other circuit (that controls the other pair) can stop the vehicle.

There’s also a proportioning valve in most vehicles, connecting the master cylinder to the rest of the brake system. It controls the pressure distribution between the front and rear brake for balanced, reliable braking performance.

The master cylinder reservoir is located on top of the master cylinder. It must be adequately filled with brake fluid to prevent air from entering the brake system.

Here’s what happens in the master cylinder when you press down on the brake pedal:

● A pushrod drives the primary piston to compress the brake fluid in its circuit

● As the primary piston moves, hydraulic pressure builds inside the cylinder and brake lines

● This pressure drives the secondary piston to compress the brake fluid in its circuit

● Brake fluid moves through the brake lines, engaging the braking mechanism

When you release the brake pedal, the springs return each piston to its initial point.

This relieves the pressure in the system and disengages the brakes.

Post time: Feb-22-2023